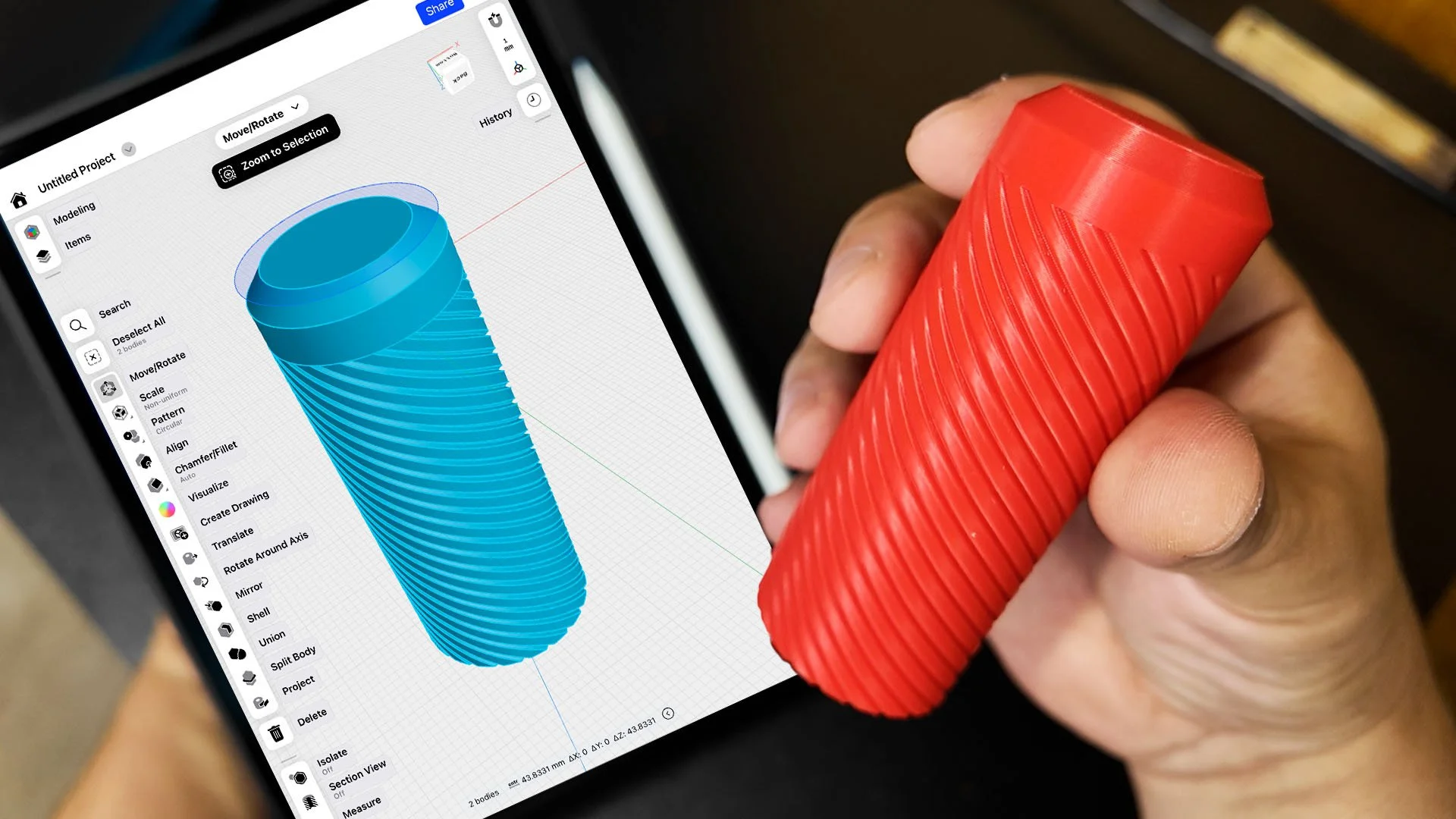

CAN I 3D PRINT MY OWN SHIFTER?

Designing your first car part from a blank screen can be tough. So we created a blank shifter you can quickly modify that will help you learn the basics creating 3d printed interior car parts.

Want to skip the guesswork and design your own parts in just a few hours…

I took everything I learned from measuring, designing, and 3d printing and turned it into a 1-Day Car Parts Design Workshop.

Learn to go from idea → CAD → 3D printed part that survives in your car, without months of trial and error.

Start [today] and unlock extra bonuses for a limited time.

START SIMPLE

The best way to get started with interior car parts is with a simple design, like a 3d printed shifter.

This design was modeled from a BMW e30 shifter knob that you can modify to fit your ride. Here’s the steps:

1. DOWNLOAD SHAPR3D

Designing your first 3d printed shifter doesn’t need to be complicated. Which is why you should download [Shapr3d here].

Shapr3d is easiest and most powerful CAD software programs we’ve used.

It even works with an iPAD and Apple pencil, but you can also download a desktop version too.

2. IMPORT THE FREE SHAPR3D BASE SHIFTER

The design has already been created, so all you have to do is download and import the base design into Shapr3d with the import feature.

But if you’re ready to start learning how to make your very own custom one-of-a-kind designs in just one day, we made a 1-day on demand workshop you can check out here.

3. MEASURE YOUR PART

Grab a measuring tool like a caliper or ruler and start taking measurements of your shifter.

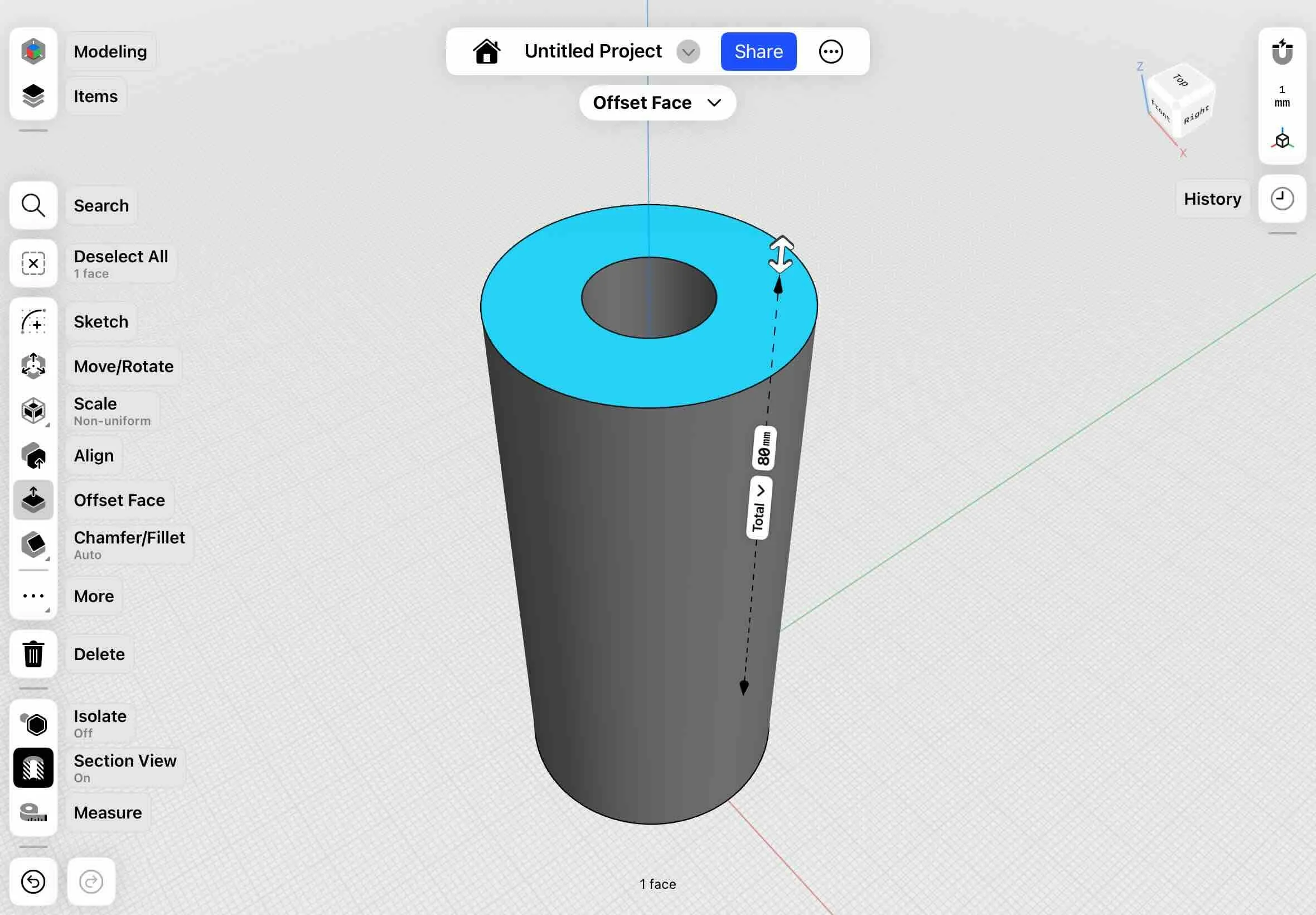

4. MODIFY THE SIZE

Use the history tool in shapr3d on the right hand menu to modify the sketch size. You can adjust the length, width, or diameter.

5. ADD YOUR OWN DESIGN

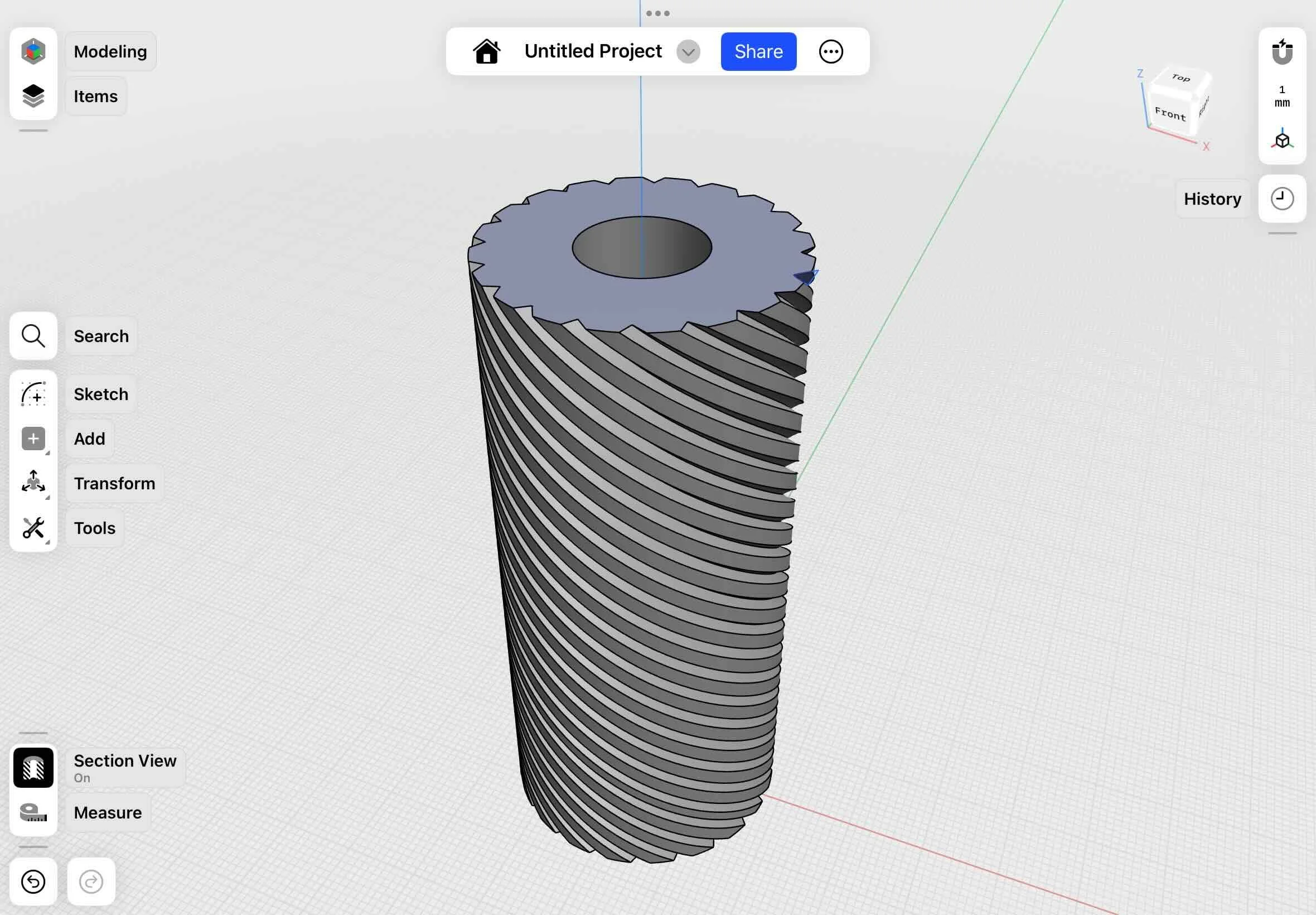

In a few easy steps you can add your own design to the outside of the 3d printed shifter knob.

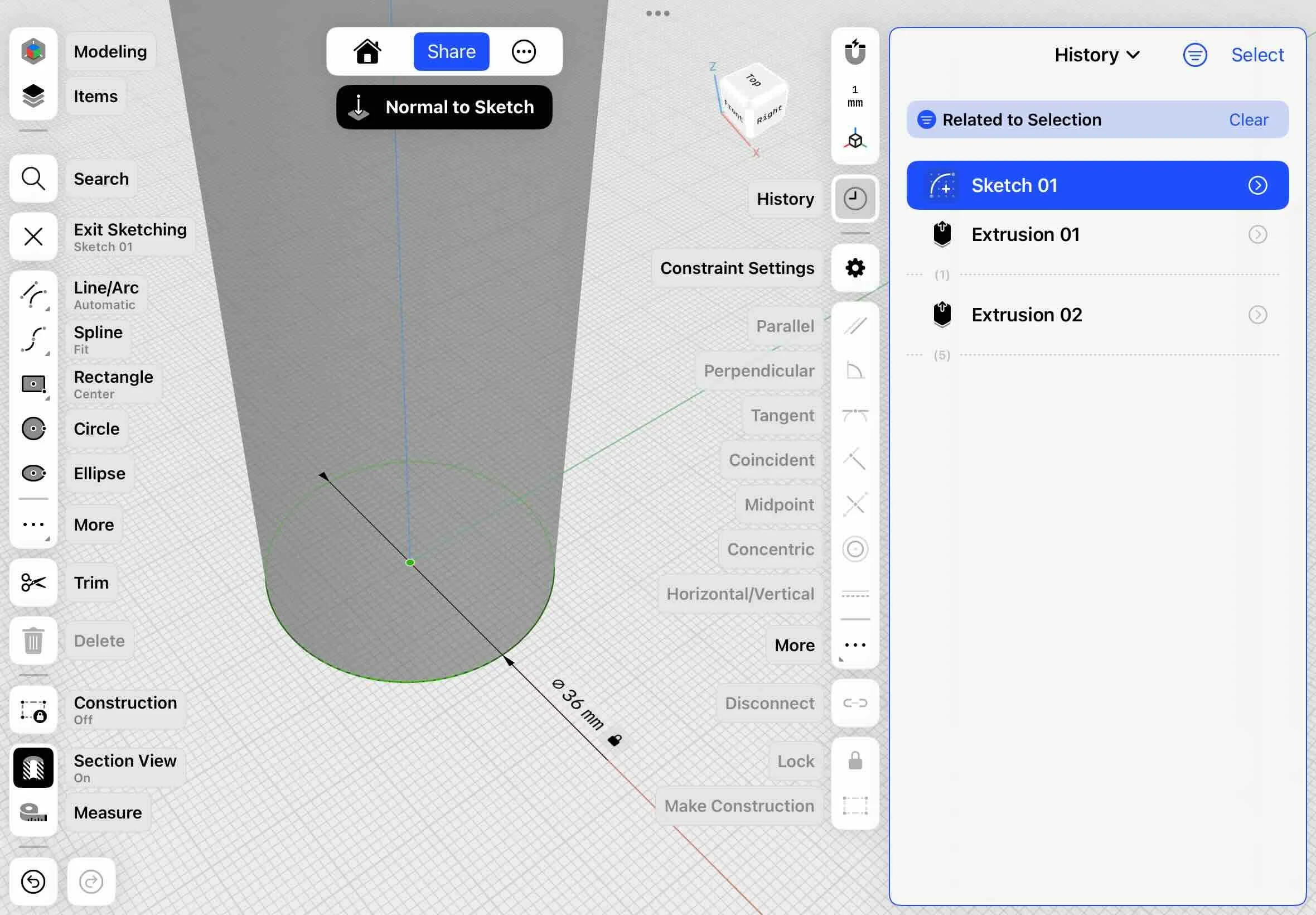

1. Draw a shape using the sketch tool. You can draw a simple triangle at the top of the shift knob.

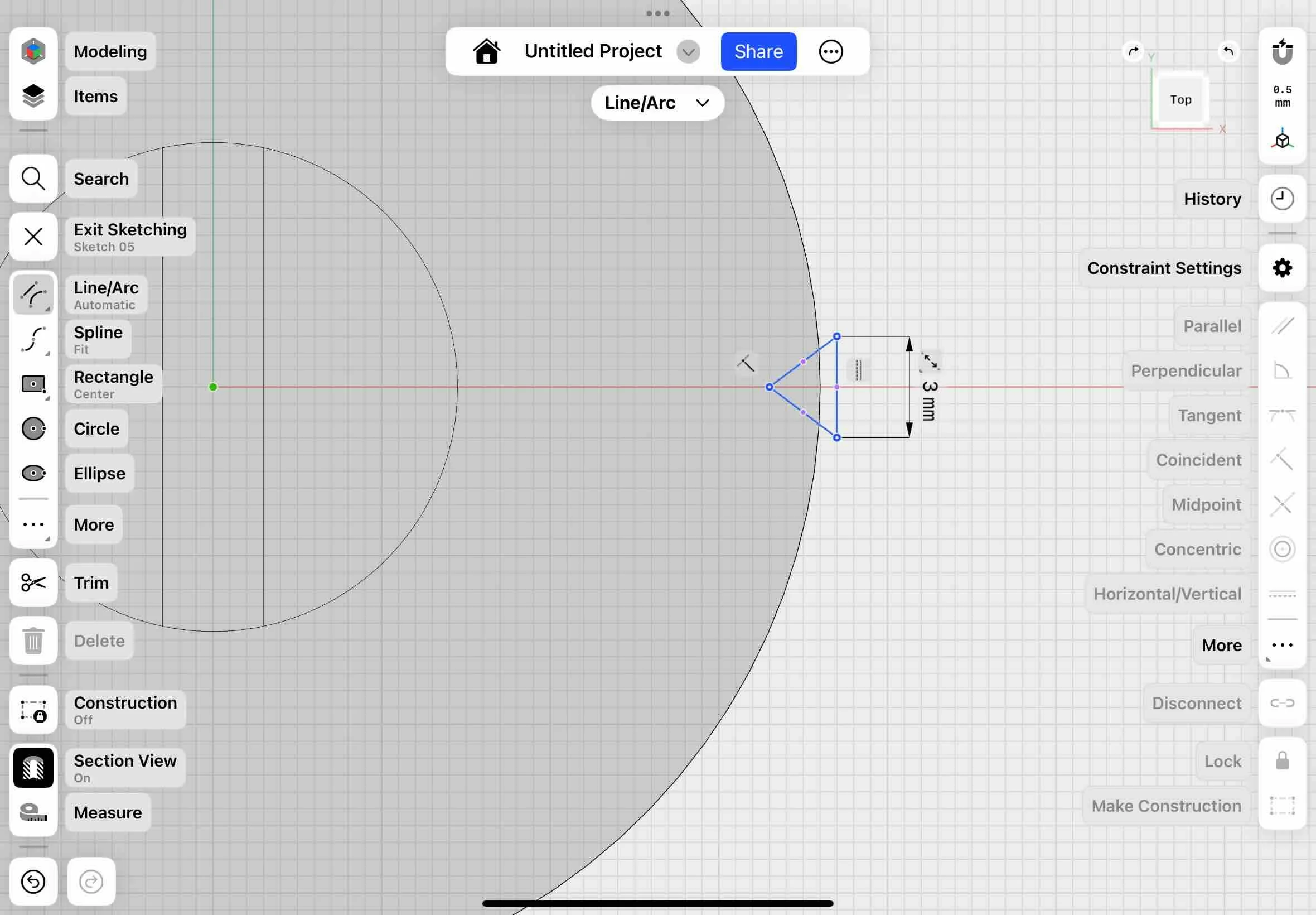

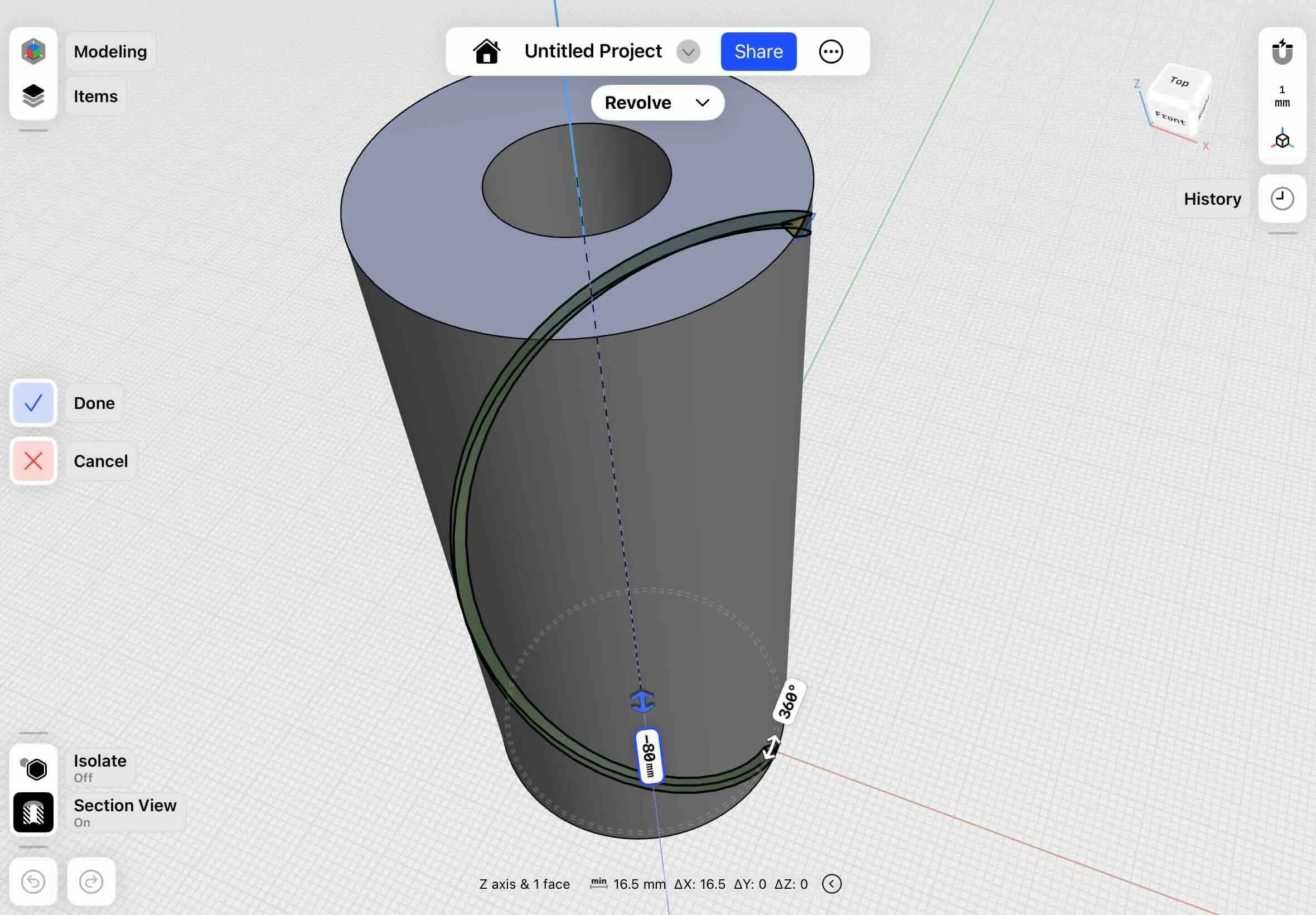

2. Exit sketch mode and select the rectangle shape. Then use the revolve tool in shapr3d to create a spiral design.

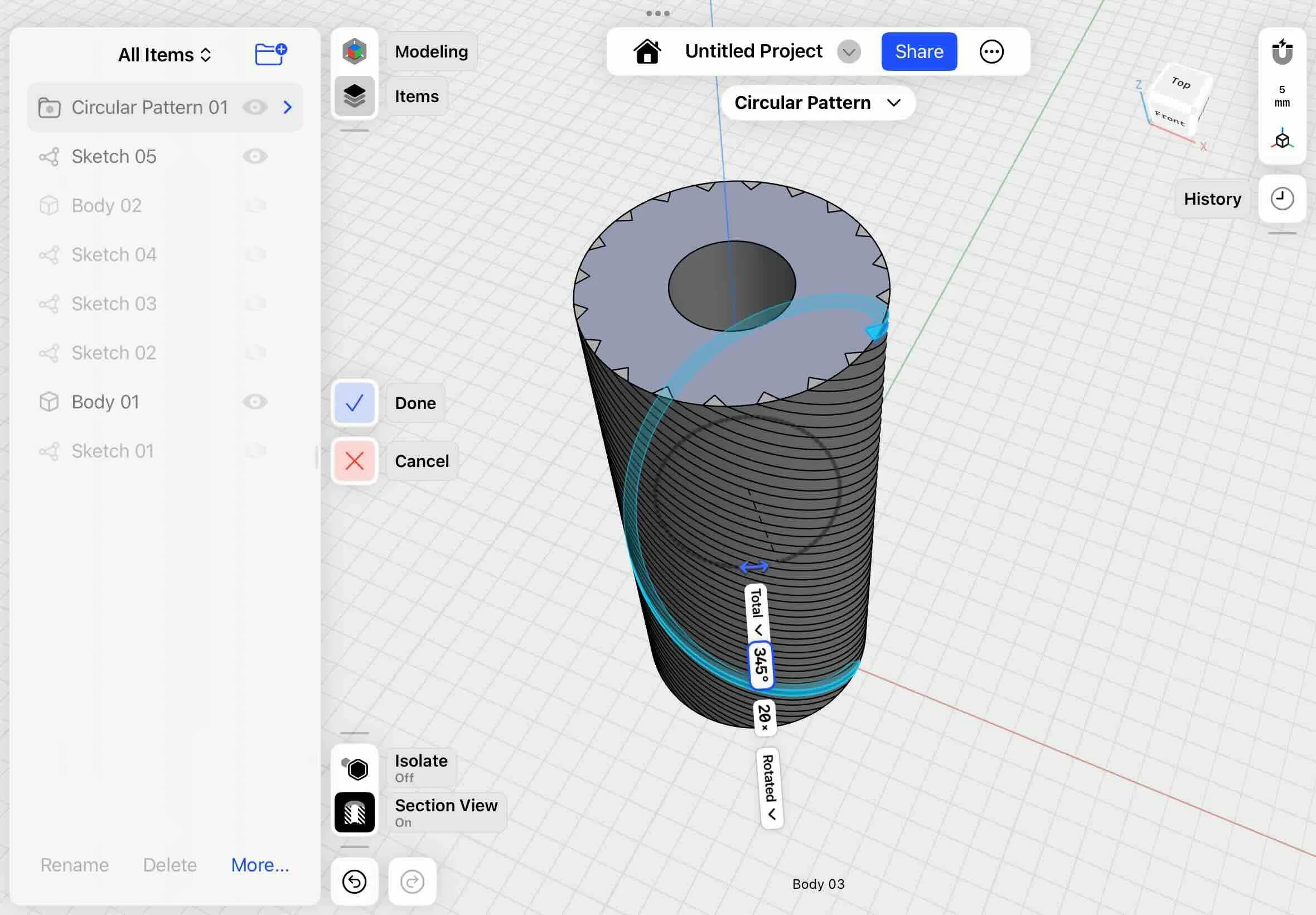

3. Select the shape and use the circular pattern to replicate the shape.

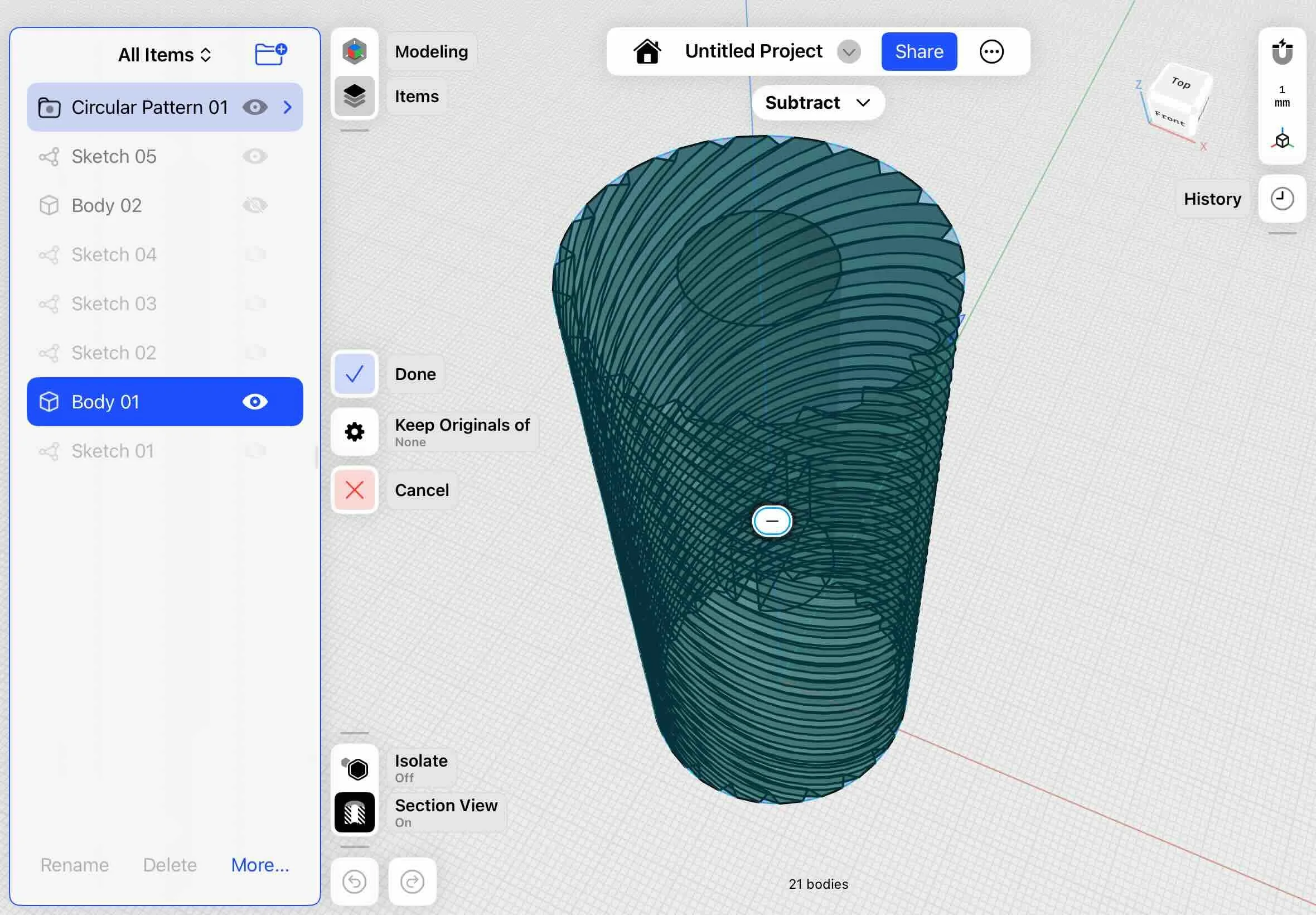

4. The last step is to make the new pattern cut out from the body of the shifter. Open the items, highlight the body and select the subtract tool.

Then select the circular pattern to subtract the pattern from the shifter body.

6. EXPORT AND PRINT THE DESIGN

Use the Shapr3d export feature to export the design to an STL file and add it to your 3d printing software to print.

💡 Note: The free version of Shapr3d exports in lower resolution. If the shape isn’t smooth enough, give the Shapr3d trial version a try.

Need a 3d printer?

Use our [3d Printer and Filament selector here] to pick the best 3d printer for car parts based on the part, budget, and size you are looking to make.

You can also send your car part design to a print-on-demand service like PCBway.com if you don’t have a 3d printer.

7. TEST FIT THE DESIGN

Here’s the shifter design

It fits perfect :)

If the size is slightly off you can go back to Shapr3D and adjust the scale using the history function.

DESIGN YOUR FIRST CUSTOM CAR PART IN JUST ONE DAY

Want to level up your ride with a skill that lasts a lifetime, then this workshop is for you.

Money Back Guarantee • Risk Free

FAQ

Q.) Is PLA good for car parts?

A.) Only for cool (below 122-140°F), non-structural interior parts or prototypes.

Q.) What’s the strongest filament for automotive use?

A.) Nylon-CF blends for strength; ASA for heat/UV.

Q.) Do I need a special 3D printer to print car parts?

A.) Enclosed printers with hardened nozzles and extruders give the best results.