3D PRINTING VS BUYING CAR PARTS: WHAT’S ACTUALLY CHEAPER?

Want to skip the guesswork and design your own parts in 1 day?

I took everything I learned from measuring, designing, and 3d printing and turned it into a 1-Day Car Parts Design Workshop.

Learn to go from idea → CAD → 3D printed part that survives in your car, without months of trial and error.

Start [today] and unlock extra bonuses for a limited time.

Why 3D Print Car Parts?

Modern 3D printers are more capable than ever—and materials like ASA, ABS, and carbon fiber blends can even work for interior (and some exterior) car parts.

With the right file and print orientation, you can get OEM-level fit at a fraction of the cost.

Here’s some real 3d printable car parts

1. BMW E30 Shifter Boot Frame

OEM Cost: $50+

3D Printer Filament Cost: $.58

Material: ASA Filament

This BMW e30 shifter boot trim frame cracked. We found a clean model online, dropped it into Bambu Studio, and sliced it with ASA filament (great for interior heat/UV).

ASA Spool price: $30

Filament used: ~$.50

Print time: ~2 hours

Result: Near-perfect OEM fit

2. Air Vent with Round Gauge Pod Insert

If you break an air vent on a classic car, trying to find a new one is impossible and even a used one will cost you. So instead, you can print a new one with a bonus vent gauge pod insert.

OEM Replacement: ~$75

Print Cost: $0.62

Bonus: Integrated 52mm gauge holder

We downloaded a free STL that turns your vent into a functional gauge pod.

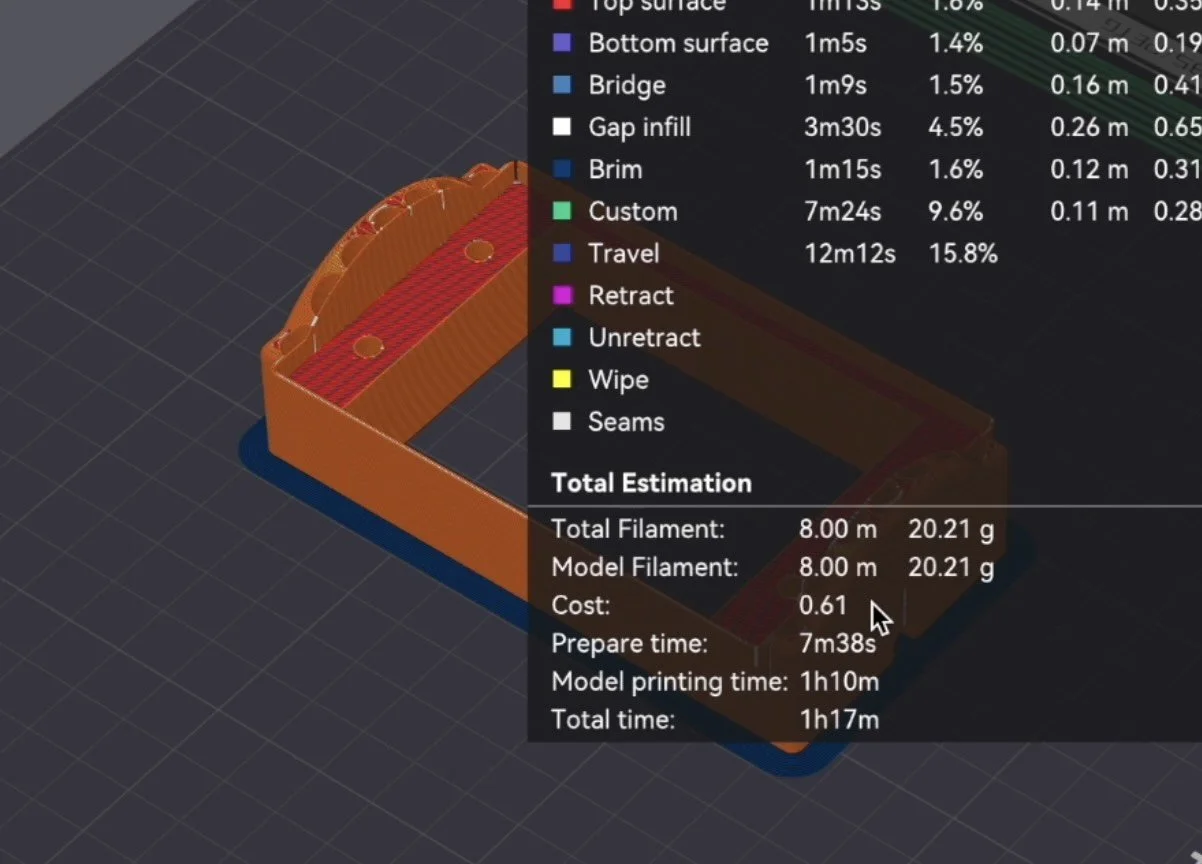

3. Vent Gauge Pod with LCD Display

Now if you want to install a mini LCD screen with a custom vent gauge insert, the cost is astronomical.

But if you build it yourself with a 3d printed insert with a custom Raspberry Pi, you can do this for under $50.

Retail Cost: $200+ w/Pre-built LCD

DIY Cost: $0.61 + ~$40 Raspberry Pi + Mini LCD

We found this LCD-compatible design via MakerWorld. It prints beautifully in ASA.

DESIGN YOUR FIRST CUSTOM CAR PART IN JUST ONE DAY

Want to level up your ride with a skill that lasts a lifetime, then this workshop is for you.

Money Back Guarantee • Risk Free

4. BMW E30 Center Console Tape Deck Replacement

OEM Cassette Replacement Cost: Up to $200

Print Cost: $3.09

Optimized slicer flat orientation:

5 hours

$3.09

Fewer supports, cleaner print

Fit: Snug and functional upgrade.

5. Custom BMW E30 Cup Holder (Ashtray Delete)

Some classic project cars are missing one of the most important things… A cup holder. Lucky for us we found a design we could send straight to the 3d printer.

🎥 For details on how we made these parts in detail, watch here on our YouTube channel:

OEM Alternative: ~$40+

Print Cost: ~$1.00

Screws into factory ashtray location with minimal supports.

Print time: ~2 hours

Fit: Like a glove

Function: Much better than OEM

How Much Money Can You Save 3D Printing Car Parts?

| Part | OEM Price | 3D Print Cost | Savings |

|---|---|---|---|

| Shifter Boot Frame | $50 | $.50 | $49.50 |

| Gauge Vent Pod | $75 | $0.62 | $74.38 |

| LCD Vent Pod | $200 | $40.61 | $159.39 |

| Center Console | $200 | $3.09 | $196.91 |

| Cup Holder | $40 | $1.00 | $39.00 |

| Total | $565 | $45.82 | $519.18 |

What Printer Did You Use to Print These Car Parts?

We used the Bambu Lab X1 Carbon for its precision and ability to print ASA and carbon-fiber-filled filaments.

But if you're on a budget, the Bambu P1S is a fantastic budget alternative enclosed printer that handles ASA and ABS too.

💡PRO TIP: To 3d print carbon or glass infused fiber the P1S will need a low cost upgrade of a hardened extruder and hotend.

How Can You Sell Your 3D Printed Car Parts?

One of the easiest ways to sell your 3d printed car parts is on eBay. We designed a custom E30 radio delete plate in Shapr3D and listed it on eBay under 5 minutes.

Comparable parts sell for $30–40

Net profit per unit: $10–15 after fees and shipping

Want to Learn More About 3D Printing Car Parts?

We’ve written in-depth guides on each part of the process—perfect for beginners or anyone looking to upgrade their car builds with 3D printing: