DESIGN AND 3D PRINT A RADIO DELETE PLATE WITH SHAPR3D

Want to skip the guesswork and design your own parts in 1 day?

I took everything I learned from measuring, designing, and 3d printing and turned it into a 1-Day Car Parts Design Workshop.

Learn to go from idea → CAD → 3D printed part that survives in your car, without months of trial and error.

Start [today] and unlock extra bonuses for a limited time.

Now let’s get to tackling a more complex project: fixing issues with a previously downloaded BMW e30 radio delete plate model which falls into 3d printing car interior parts.

THE BIG PROBLEM

The original pre-made radio delete plate I downloaded from thingiverse was super bulky and had super thin clips that failed during installation.

Our fix? Design a new radio delete plate from scratch.

The first measurement we needed to correct was the depth of the radio delete plate insert.

The second was the lip where our newly designed clips would be.

Rather than relying on thin tabs, we built beefier clips—and added more of them into the design.

MODIFY THE DESIGN FOR YOUR RIDE

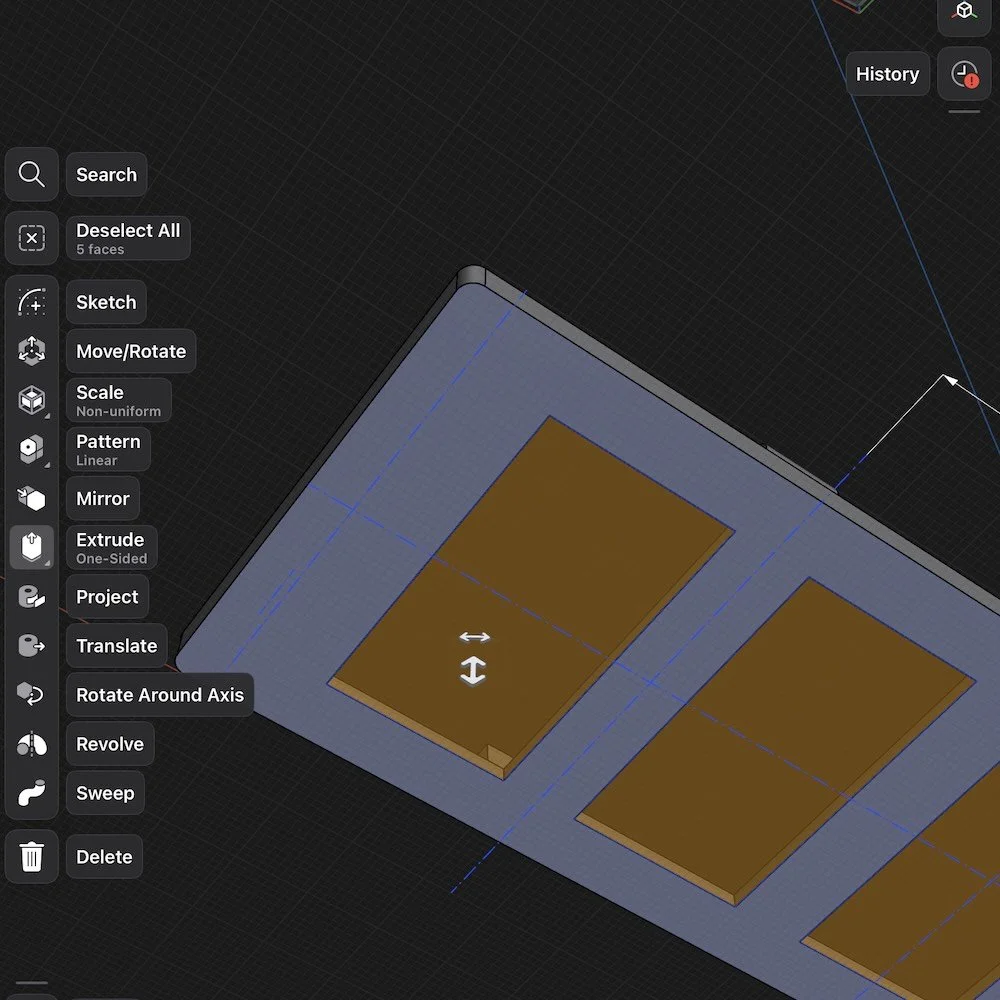

With the [FREE version of Shapr3d] you can create and modify the pre-made design. Shapr3d is by far one of the simplest CAD software programs out there.

After you download Shapr3d, download the [pre-made radio delete plate design here].

Using the sketch tool in Shapr3d, you can modify the size of the radio delete plate to fit your cars measurements.

You can add or remove the rectangular inserts based on your application with the extrude tool as well.

PRINT THE PART

Once you have the right size, you can export the design as an STL file and load it into your favorite 3D printing slicer software.

💡 PRO TIP: Use UV-resistant ASA filament, which is perfect for in-car applications thanks to its ability to withstand temperatures up to 220°F.

And if you need help picking out a 3d printer for car parts check out this [3d printer selector for car parts here].

The result? A snug-fitting, durable 3d printed radio delete plate with solid mounting clips.

But there’s one more trick…

You can even 3d print your part in more than one color with an AMS or automatic material system [from Bambu Lab].

Just insert your radio delete plate and svg image into your slicing software, center your parts, reduce the height of the image, and merge the objects.

We have an entire guide on multi-color 3d printing car parts here.

The result? A secure, custom-designed panel that fits like a glove.

DESIGN YOUR FIRST CUSTOM CAR PART IN JUST ONE DAY

Want to level up your ride with a skill that lasts a lifetime, then this workshop is for you.

Money Back Guarantee • Risk Free