WHAT FILAMENT IS GOOD FOR CAR PARTS?

If you want to start 3d printing your own car parts, one of the most important things is picking the RIGHT filament…

🔥 ASA – High heat + BEST UV resistant.

🔥 ABS – High heat resistance; Medium UV Resistance.

💪 Nylon – Tough, impact-resistant; Dry before printing.

🛡️ Polycarbonate (PC) – Very high heat resistance.

❌ Choose the wrong filament → your vent gauge melts

❌ Wrong choice → clip cracks

❌ Wrong choice → exterior trim fades in one summer

Choosing the right filament avoids $100–$1,000 mistakes. Let’s review what actually works — plus where to get each one.

Want to skip the guesswork and design your own parts in 1 day?

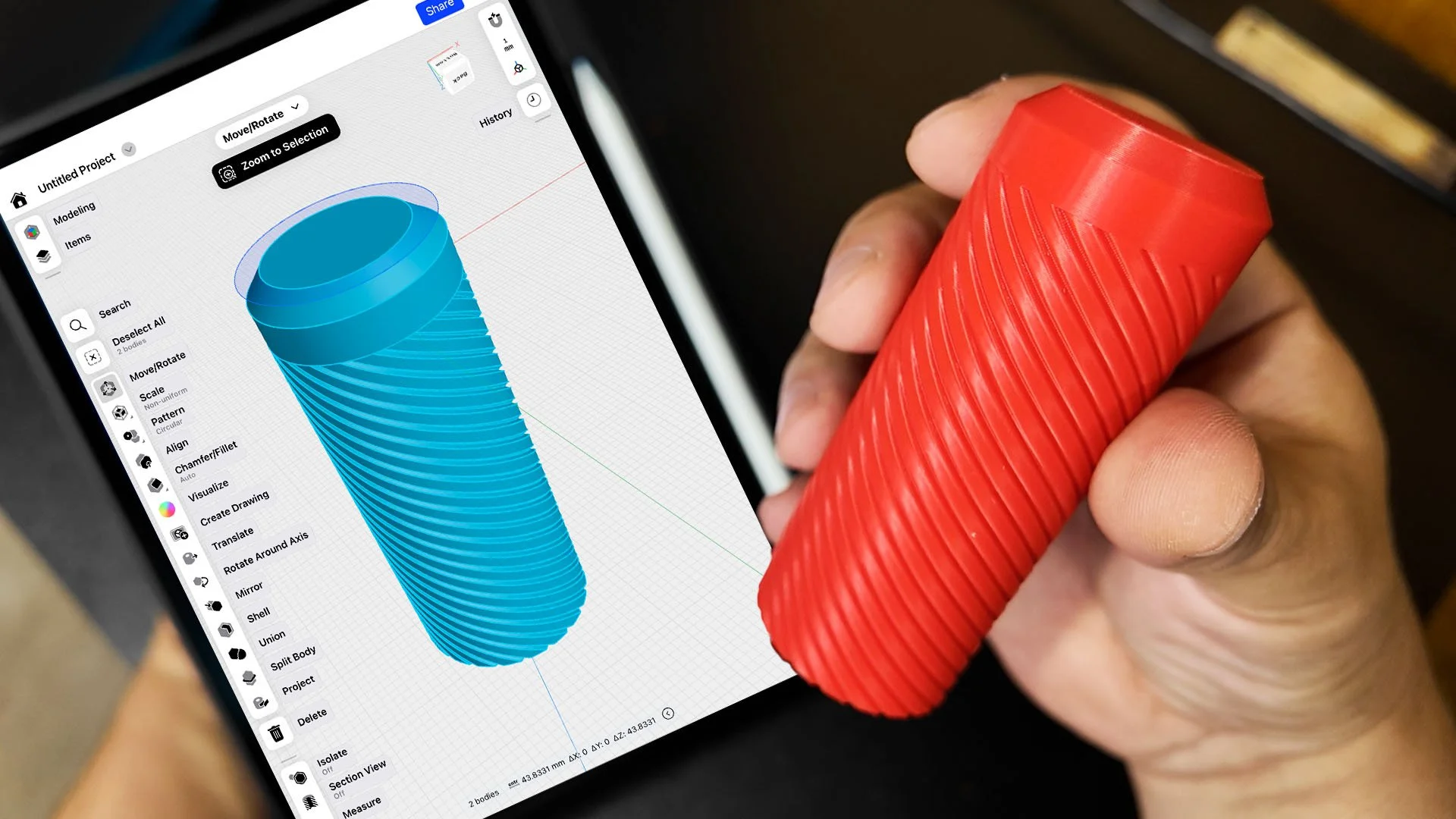

I took everything I learned from measuring, designing, and 3d printing and turned it into a 1-Day Car Parts Design Workshop.

Learn to go from idea → CAD → 3D printed part that survives in your car, without months of trial and error.

Start [today] and save 25% off with discount code SAVE25.

PLA Filament

One of the most common 3d printing filaments you’ll hear of is PLA or Polylactic acid filament. It’s a thermoplastic polyester made mostly from corn starch or sugar cane.

PLA is easy to print due to its low melting point of around 145°C or 293 degrees Fahrenheit compared to other filaments.

CAN PLA BE USED FOR CAR PARTS?

If you leave a PLA 3d printed car part in your cars dashboard like a vent gauge on a hot sunny day, it will melt in the form of sagging.

I’d only recommend PLA for prototyping a part for fitment and testing.

SO WHAT 3D FILAMENT IS GOOD FOR CAR PARTS???

Let’s start with the next two options vs PLA that can withstand heat a bit better than PLA.

PETG (Polyethylene Terephthalate Glycol) and ABS (Acrylonitrile Butadiene Styrene)…

PETG FILAMENT:

Heat Resistance: PETG offers moderate heat resistance, with an HDT lower than that of ABS.

Glass transition temperature: of approximately 80-85°C (176-185°F).

Durability: PETG provides a good balance between flexibility and strength, making it less prone to cracking under stress.

UV Resistance: PETG has a slightly better UV resistance compared to ABS, preventing it from discoloration that ABS can face.

CAN PETG CAR PARTS MELT IN THE SUN?

• While PETG performs well under moderate heat conditions, prolonged exposure to high temperatures, such as those experienced inside a car can also cause PETG car parts to soften

For 3d printed parts that will be exposed to direct sunlight and high temperatures you should consider filaments with an even higher heat resistance like:

ABS FILAMENT:

ABS Heat Resistance: ABS has a higher heat deflection temperature (HDT) compared to PETG, making it more suitable for parts exposed to elevated temperatures. It has a glass transition temperature: of around 105°C (221°F).

ABS Durability: Known for its toughness, ABS can withstand significant stress and impact, which is beneficial for functional car components.

ABS UV Resistance: ABS is susceptible to UV degradation, which can lead to discoloration and brittleness over time.

Great for interior car parts like gauges, delete plates, and trim pieces where higher heat resistance is absolute, ABS is the better choice.

💡 PRO TIP: ABS requires a hotter 3d printer bed and hot end. You’ll also want to 3d print ABS in an enclosure, or you can face warping issues of your part while its printing.

WHAT IS THE BEST FILAMENT FOR DURABLE CAR PARTS?

When durability is a primary concern for your 3d printed car parts, especially for functional moving parts filaments reinforced with fibers mixed with ABS or ASA are the way to go.

The only downside is they can be much harder to print and sometimes require a 3d printer hot end upgrade…

You’ll also want to 3D print with an enclosure to prevent warping like the Centauri Carbon or Bambu Lab H2S.

Also make sure you have your 3d printer in a properly vented area. Certain filament fumes can be hazardous to breath.

But having the right filament and setup doesn’t solve every problem. The next challenge I ran into was finding the right 3d printable car part. Some worked, others not so much, but the biggest problem was finding pre-made STL models.

So I spent months trying to figure out CAD and finally came up with a process that actually worked. And if you’re ready to make your own ideas or parts come to life, I packaged it all up here. That way you don’t have to spend wasted months on trial and error like I did.

ABS / ASA Carbon Fiber-Reinforced Filaments:

ABS / ASA Strength and Stiffness: The addition of carbon fibers increases the tensile strength and stiffness of the printed parts, making them suitable for load-bearing parts like plastic brackets and engine bay wire clamps

ABS / ASA Heat Resistance: These composites often exhibit improved heat resistance of 98°C (208°F) for ABS-CF and 110°C (230°F) for ASA-CF which is beneficial for automotive environments.

ABS / ASA Lightweight: Despite their strength, carbon fiber-reinforced parts remain lightweight, an essential factor in automotive design.

Here’s some of our car parts for our e30 made with ASA filament:

🎥 Watch more tests on different filaments on our YouTube Channel:

Nylon (Polyamide) Filaments:

Nylon Durability: Nylon is known for its excellent mechanical properties, including high tensile strength and impact resistance.

Nylon Heat Resistance: It offers good heat resistance, suitable for under-the-hood applications up to 180°C (356°F)

Nylon Moisture Sensitivity: Nylon is hygroscopic, meaning it absorbs moisture from the environment, which can affect its properties. Proper storage and drying are essential.

BEST FILAMENT FOR ENGINE BAY

The engine bay of a car presents one of the most demanding environments for 3D printed parts, with exposure to high temperatures, chemicals, and mechanical stress.

You’ll need a polycarbonate or nylon based filament.

Polycarbonate (PC):

PC Heat Resistance: Polycarbonate has a high heat deflection temperature, often exceeding 228°C (442°F), making it suitable for under-the-hood applications.

PC Strength: PC is known for its exceptional strength and impact resistance, ensuring durability in demanding conditions.

PC Chemical Resistance: It offers good resistance to various automotive fluids and chemicals.

High-Temperature Nylons (e.g., PA6-CF, PAHT-CF):

PA Heat Resistance: These materials are engineered to withstand higher temperatures up to 215℃ (419°F) suitable for engine bay environments.

PA Mechanical Properties: The addition of carbon fibers enhances stiffness and strength, making them ideal for functional components.

For engine bay parts, filaments like polycarbonate and high-temperature, carbon fiber-reinforced nylons are recommended due to their superior heat resistance and mechanical properties.

Just make sure you have a printer with a hardened steel hot end and extruder.

DESIGN YOUR FIRST CUSTOM CAR PART IN JUST ONE DAY

Want to level up your ride with a skill that lasts a lifetime, then this workshop is for you.

Money Back Guarantee • Risk Free