HOW TO 3D PRINT A CENTER CONSOLE WITH A MAGSAFE PHONE MOUNT

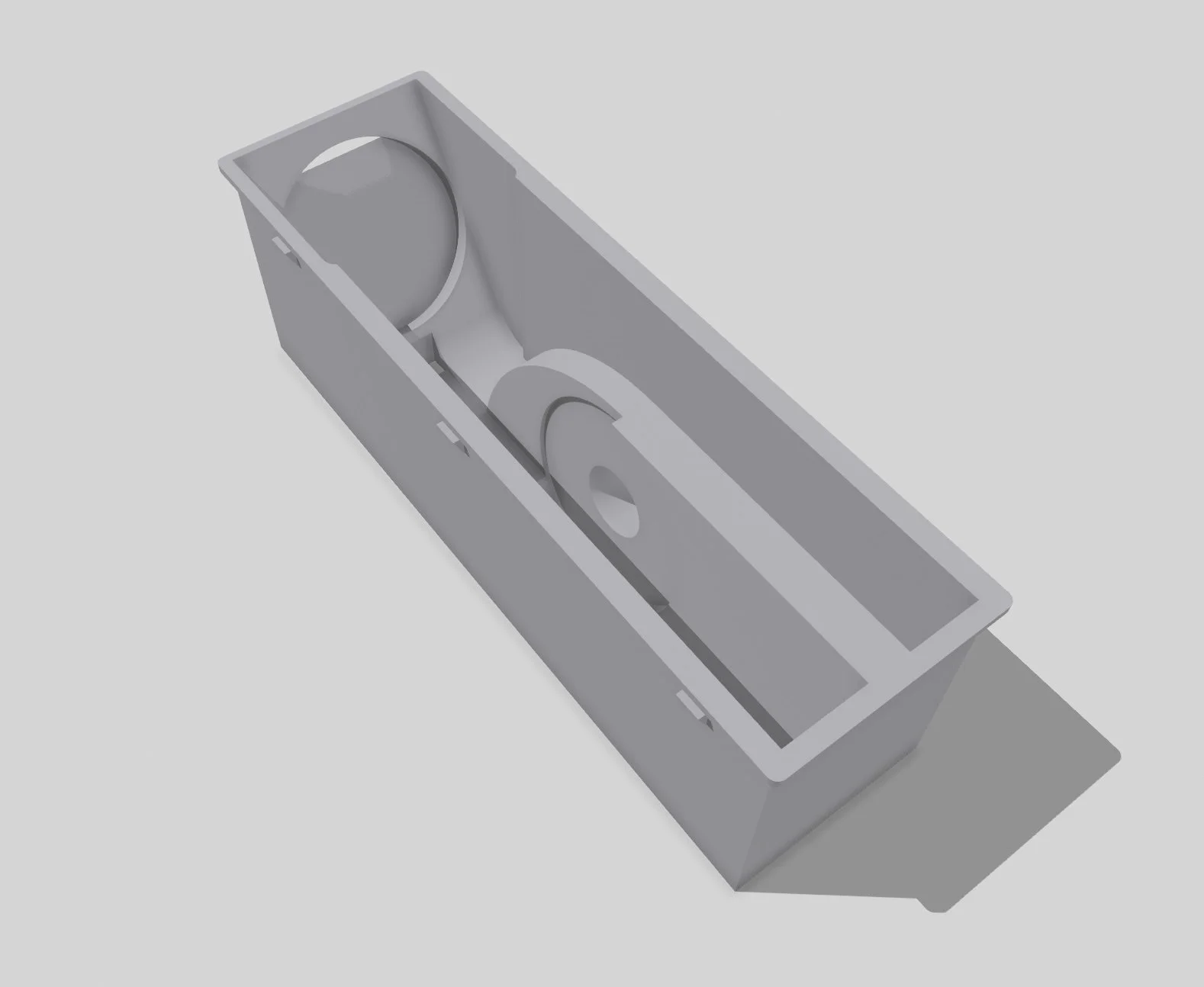

Most 3d printed center console “mods” are just… cup holders. This one turns your console into a clean, modern charging station: a phone mount with MagSafe charging (plus optional AirPods charging)

Below is the exact workflow from the build—compressed into quick steps so you can get a win fast.

But if you want to skip the guesswork and start designing your own parts in 1 day…

I took everything I learned from measuring, designing, and 3d printing and turned it into a 1-Day Car Parts Design Workshop.

Now lets dive into the 3d printed center console mod

TOOLS & MATERIAL

Hardware: 2 MagSafe Style magnetic wireless chargers from Amazon

3D Printer: Centauri Carbon or Bambu Lab H2S

3D Printer Material: ASA Filament (heat + UV resistant)

Filtration: Fume extraction or HEPA/activated carbon air purifier

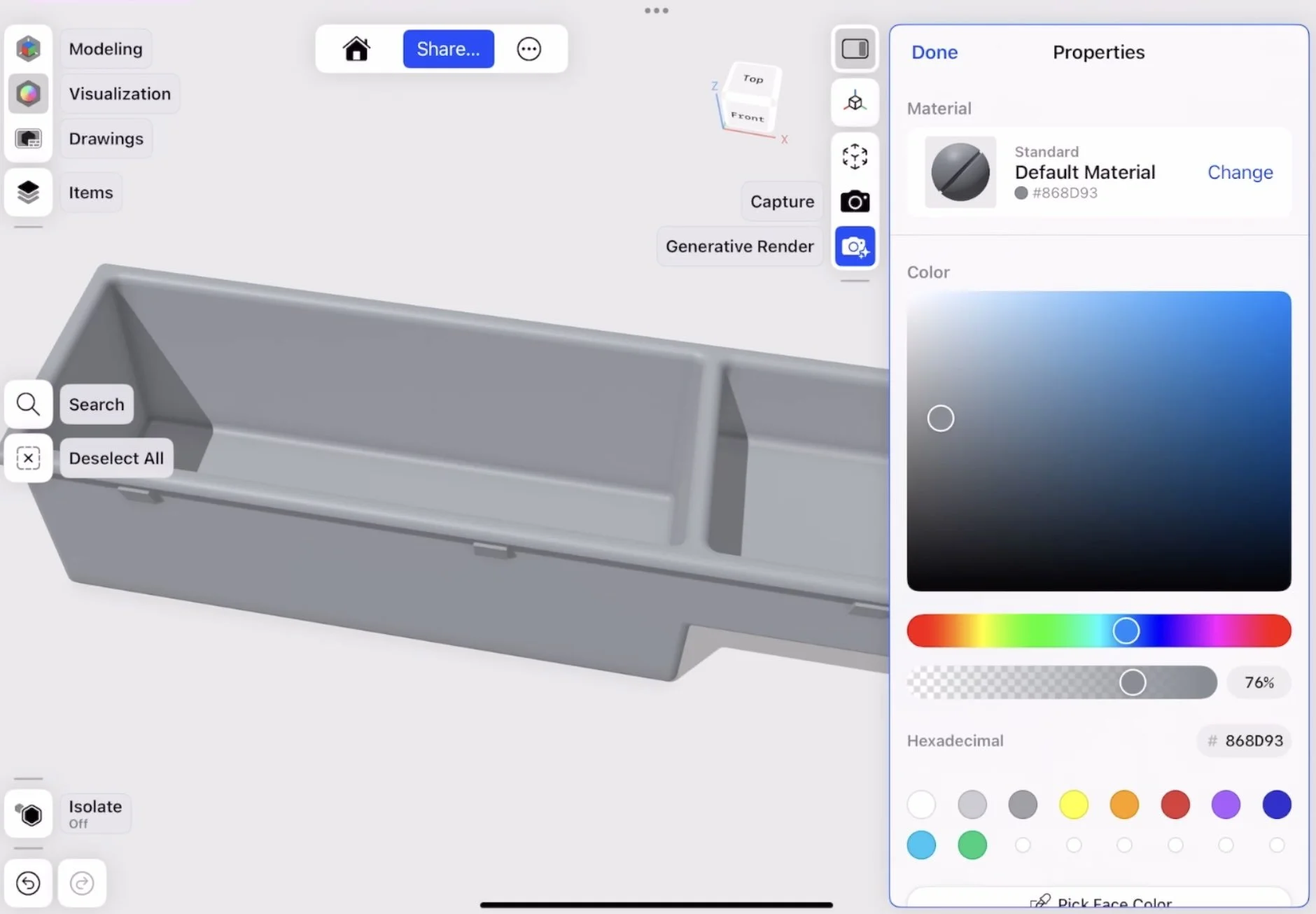

CAD Software: Shapr3D (works great on iPad + Apple Pencil, and you can reopen the same project across devices)

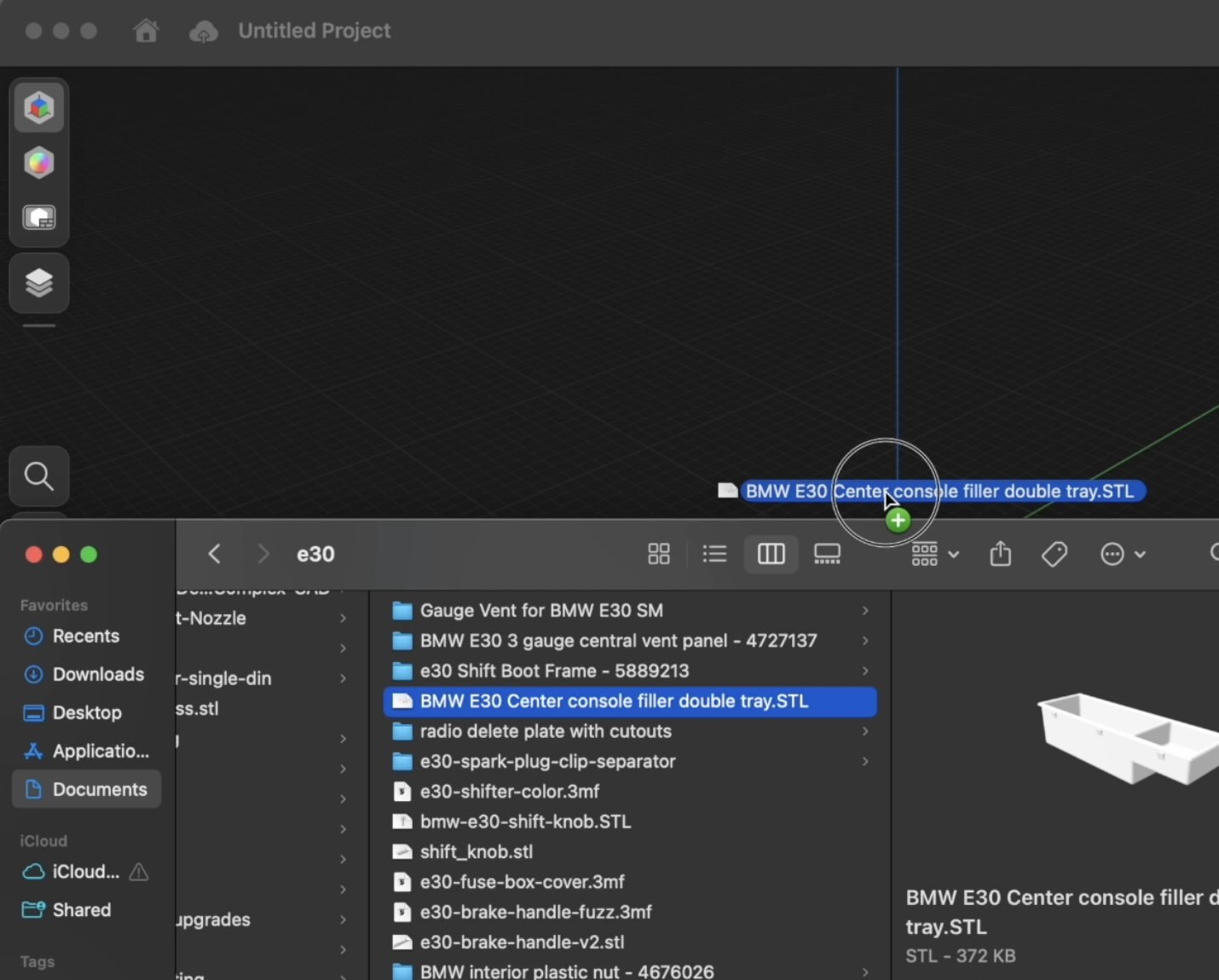

OPTION A: PRINT PRE-MADE DESIGN

If you have a BMW e30, the existing STL will fit your console opening.

Slice the STL as-is in your 3d printer software

Print in ASA (final-use material for heat + UV resistance)

Install in the console

Add wireless chargers

Insert into console

That’s it. If it fits clean and feels solid, you’re done.

OPTION B: MAKE A CUSTOM VERSION FOR YOUR RIDE

If you need to modify an existing 3d printed car part design, don’t fight trying to adjust the STL in your 3d printing slicer software —trace and rebuild it clean with Shapr3D.

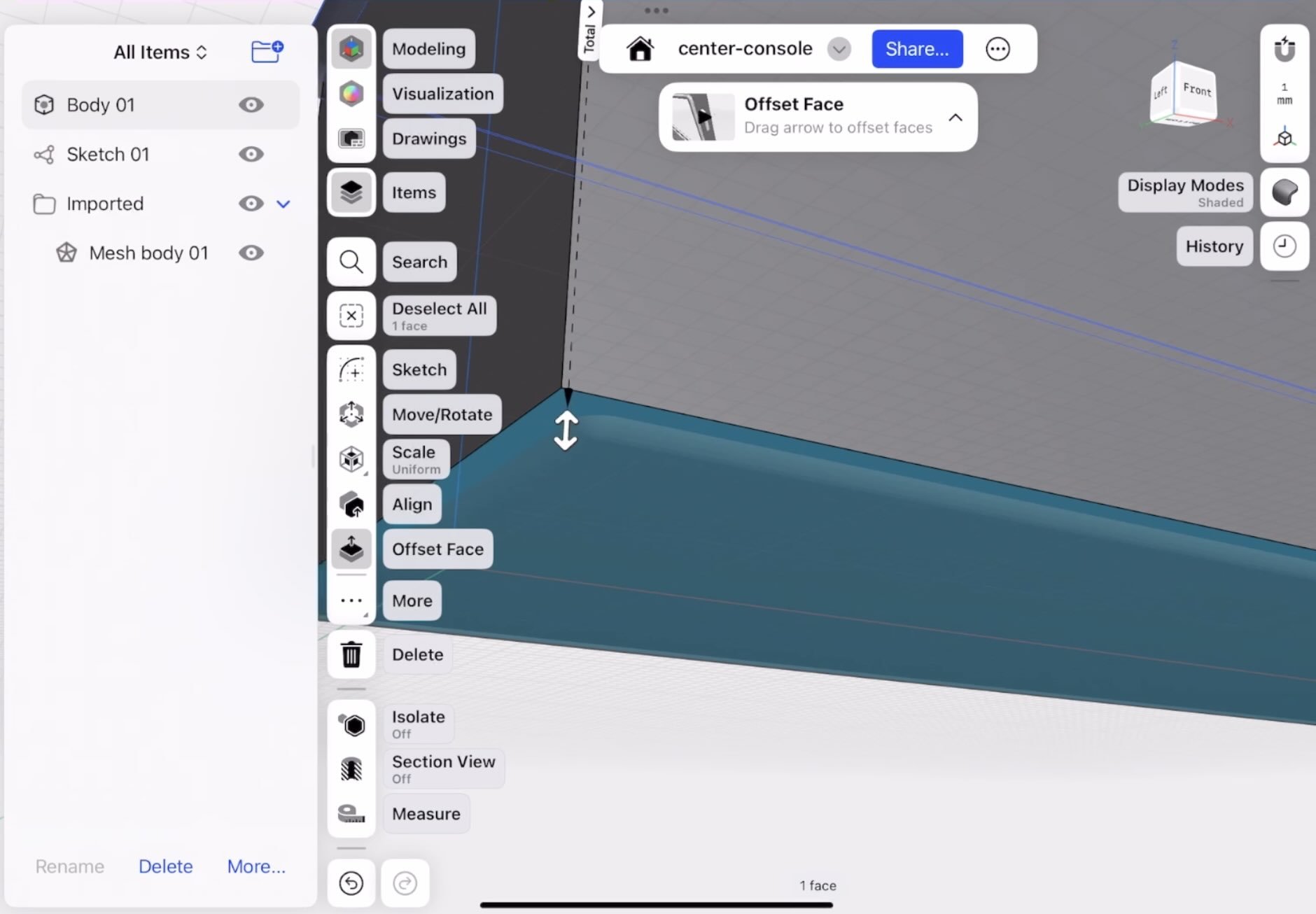

Step 1: Import the STL into Shapr3D

Step 2: Lower opacity of the imported STL so it becomes a “ghost template”

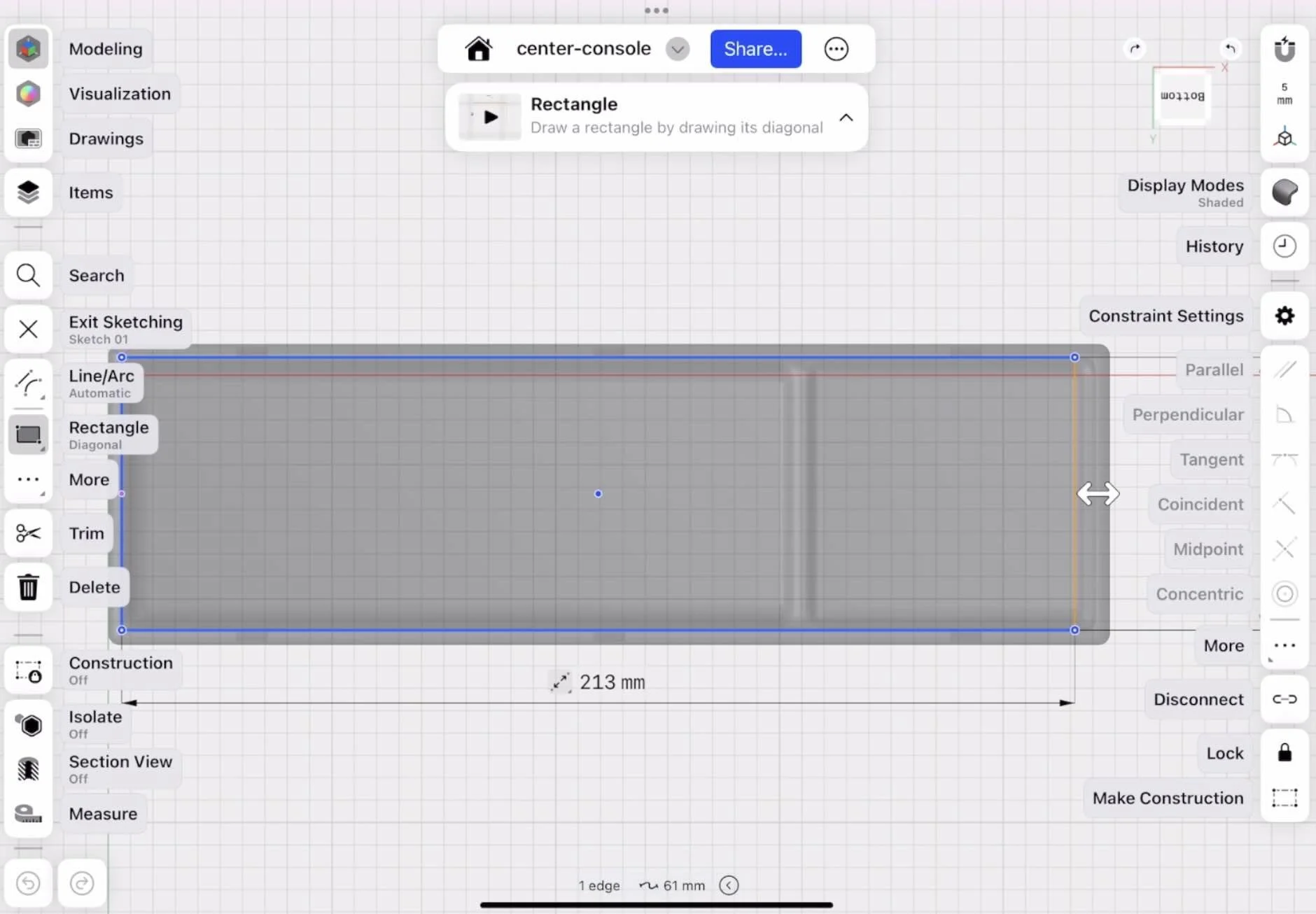

Step 3: Trace simple sketches on top of it

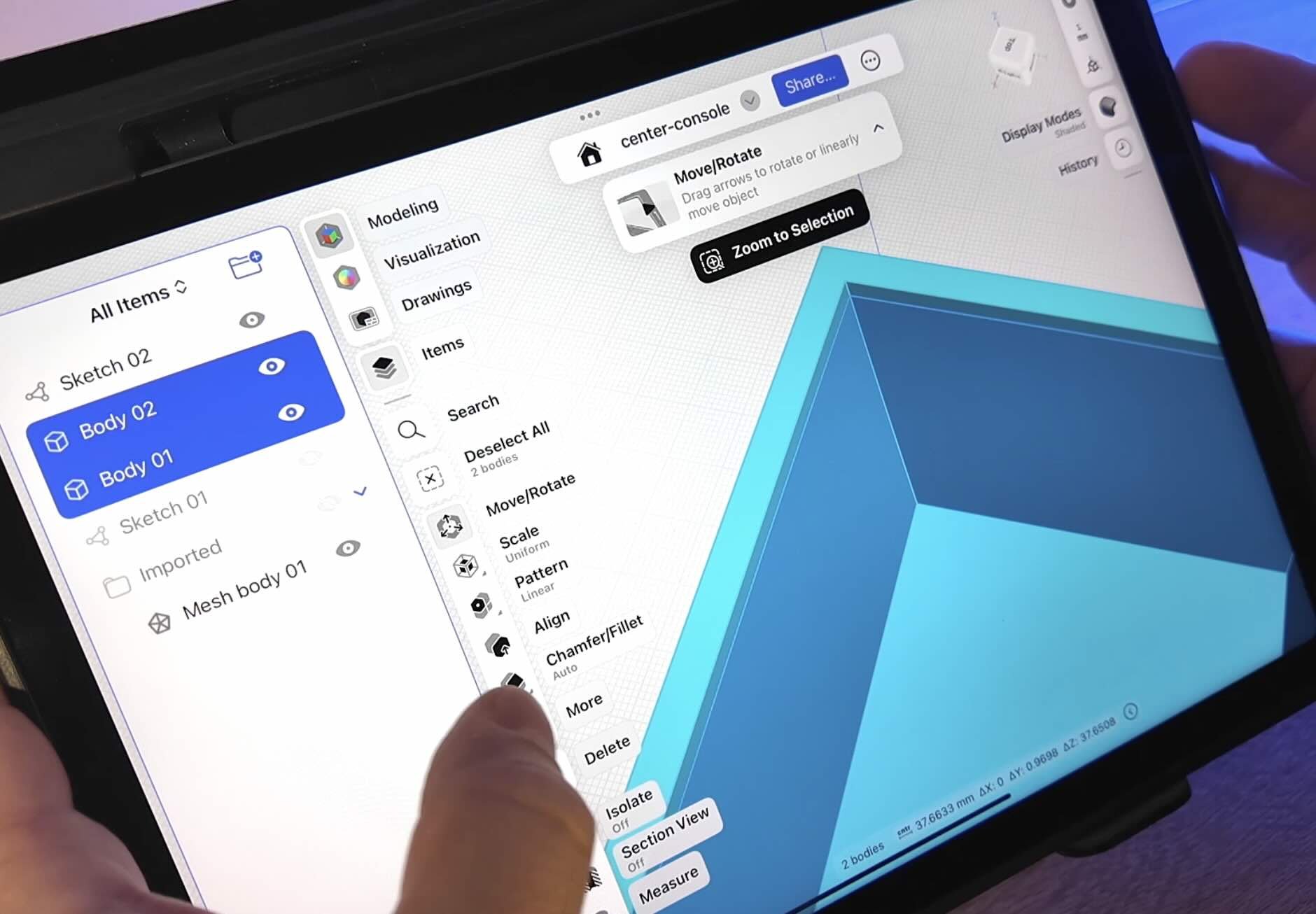

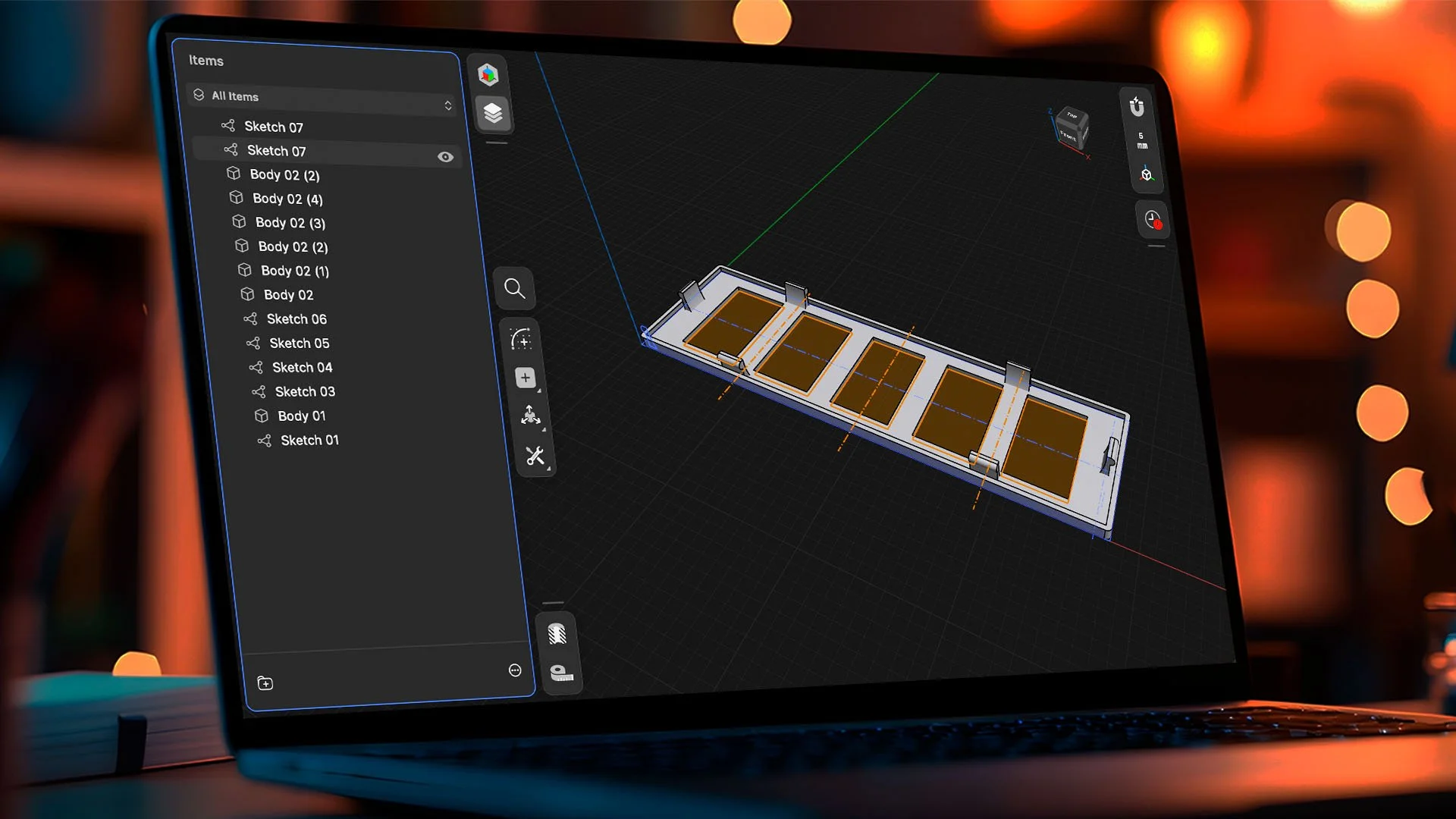

Top outline (the main shape)

Lip outline (the ledge that sits on the console opening), if the part has one

Extra parts (the clips on the side of the center console)

Step 4: Extrude your sketches into bodies to match the imported STL

Step 5: Union/Combine extruded bodies into one solid body

Step 6: Hide the imported STL and export the new design as an STL and print.

Now you’ve got a clean, editable CAD model you can modify easy—without dealing with the 3d printer slicer software limitations.

But if you need more help learning the basics of designing 3d printed car parts, we put together a workshop just for automotive enthusiasts you can access below.

DESIGN YOUR FIRST CUSTOM CAR PART IN JUST ONE DAY

Want to level up your ride with a skill that lasts a lifetime, then this workshop is for you.

Money Back Guarantee • Risk Free