Whats the Best Welder for a Beginner?

Our project cars are in desperate need of some body work repairs and that’s where the Eastwood MP140i Multi Process Welder comes in.

We choose to start with MIG welding which requires welding gas. The welding gas protects the weld from contaminates in the air. Now you could start with a flux core welder that doesn’t use gas (lower cost), but you may have trouble with blowouts on thinner automotive sheet metal which could potentially create more work.

So for a beginner, what’s the best welder? We ended up picking the Eastwood MP140i multi-process welder. Eastwood sells automotive tools focused around the DIYer, and their welder is no different. The MP140i comes with everything you need (minus a gas cylinder) which will cost around $500. You can also use code BUILD5 for an additional 5% off your Eastwood.com order. The great thing about the MP140i is that it only needs 120v electricity to run. Most folks don’t have a spare 220v outlet, which makes this great for beginners. If you ever want to try performing different types of welding such as stick, TIG, or flux the MP140i supports that too.

So we purchase a gas bottle and filled it with 75% Argon and 25% CO2 gas mix which is recommended for MIG welding. When looking for gas welding, I’d recommend you buy a gas cylinder online. Local gas refill places will charge you an arm and a leg for a new bottle. Once you have a bottle, you can get it filled up from places like Northern Tool, Tractor Supply, or a nearby Airgas store. Fair warning Airgas will be much more expensive.

Setting up the MP140i is pretty easy, but you should absolutely READ the manual and follow ALL safety procedures (operate at your own risk). Make sure you purchase and wear a proper welding mask and flame retardant clothing. You should also have a proper fire extinguisher nearby. A welding blanket is also recommended which can be used to cover up any nearby flammable items.

Welding Safety Gear (Welding Mask, Gloves, Shirt, and blanket)

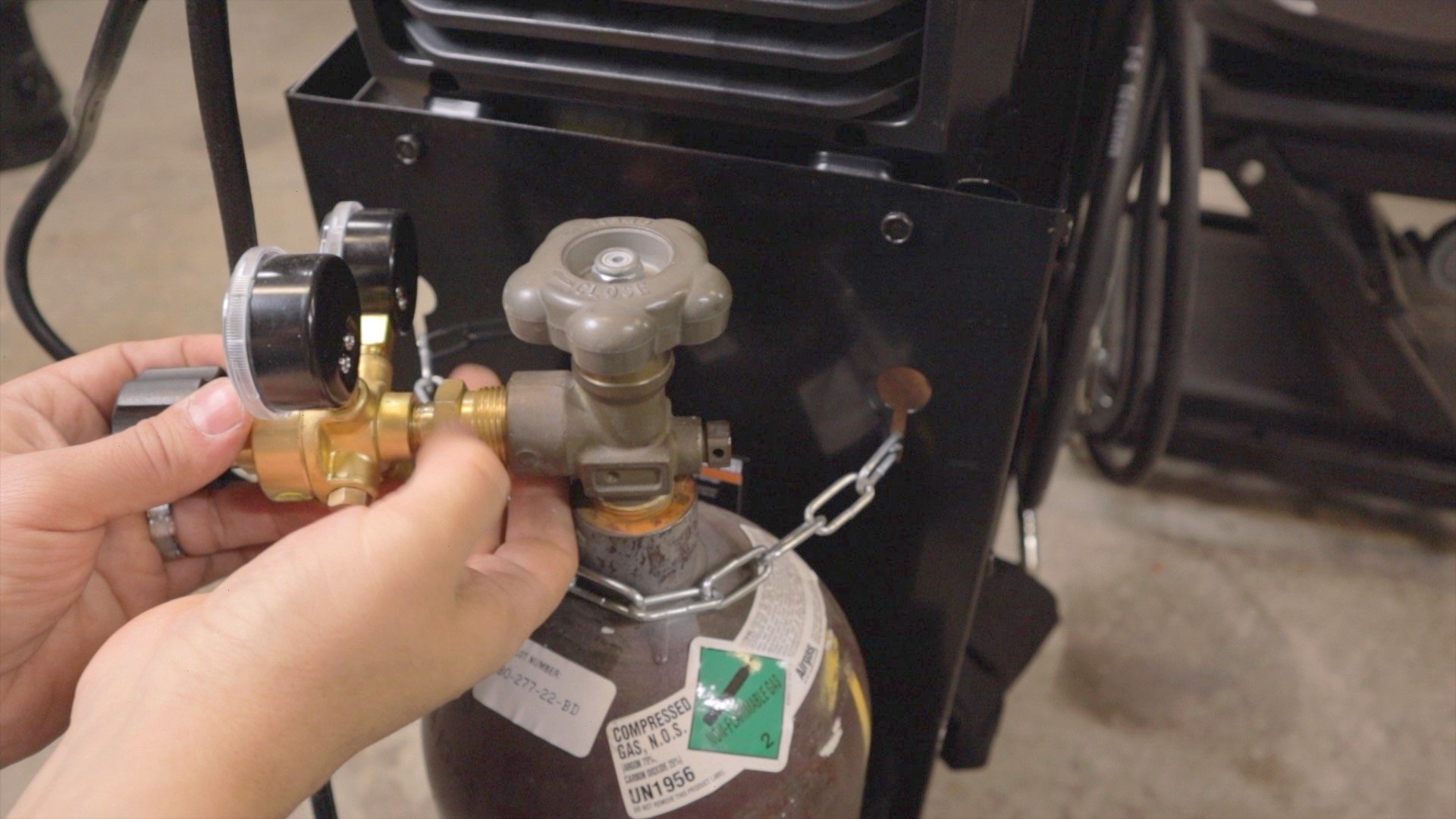

Connecting MP140i included Gas Regulator and Pressure Gauge into 40 CF Welding Gas on Welding Cart

We also recommend purchasing a welding cart and Eastwood sells one with drawers. The drawers are nice because you can then organize all your welding accessories in one place. Once you have some welding gas, you can then set the gas and welder up on the cart. Hook up the regulator and attach the hose from the regulator to the back of the gas port of the MP140i (both included with the MP140i). Don’t over-tighten the connectors and don’t use pipe thread or sealant which will cause gas leakage. Then check for gas leaks using some gas leak detector solution.

After you’ve hooked up the gas, it’s time to attach the MIG torch and load the welding wire (both included with the Eastwood MP140i). The MIG torch slides into the front port and locks in place with a wing nut from the inside of the welder. You can then connect the ground wire and polarity cable into the correct slot called out in the manual for MIG. Set the machine to MIG and load the the MIG 0.023 welding wire by placing it on the spool and feeding the wire into the guide pipe while the tension arm is in the unlatched position. The tension arm comes setup for 0.023 wire and locks easily in place.

Loading MP140i Guide Pipe with included 0.023 Welding Wire

Welding 16 gauge steel with the Eastwood MP140i using MIG welding with GAS and Welding Helmet

Plug the welder into your standard 120v outlet and press the trigger to feed the wire through the MIG torch. Open up the gas cylinder and set the correct wire speed and voltage based on your thickness of material. And don’t forget to hook your ground clamp and make sure your welder is setup for the correct polarity based on the type of welding you’re doing. Now you’re ready to start welding.

The Eastwood Welder wasn’t difficult to use. The most complicated part of welding on the Eastwood is finding the correct voltage and wire speed settings based on your material thickness. The helper chart inside the welder is a good starting point, but will require additional adjustments.

The best thing we like about the Eastwood MP140i is that it supports TIG, MIG, Flux Core, and stick welding. After MIG welding some new pieces of metal into our BMW e30 project car, we ran out of gas and all gas stores were closed. We went to Harbor Freight and bought some flux core wire, changed polarity and started flux welding. The flux welding worked, but sometimes requires more grinding and using a copper backing plate to prevent blowouts on larger gaps.

👇 DETAILED SETUP OF MP140i WELDER👇

We assume no liability for anything you choose to do to your automobile/home before, or after reading or watching one of our videos. Working on your automotive/home and using any information from this website should be done at your own risk.

By using our affiliate links, you are helping support our site and us as creators! Thank you!